Inoculants

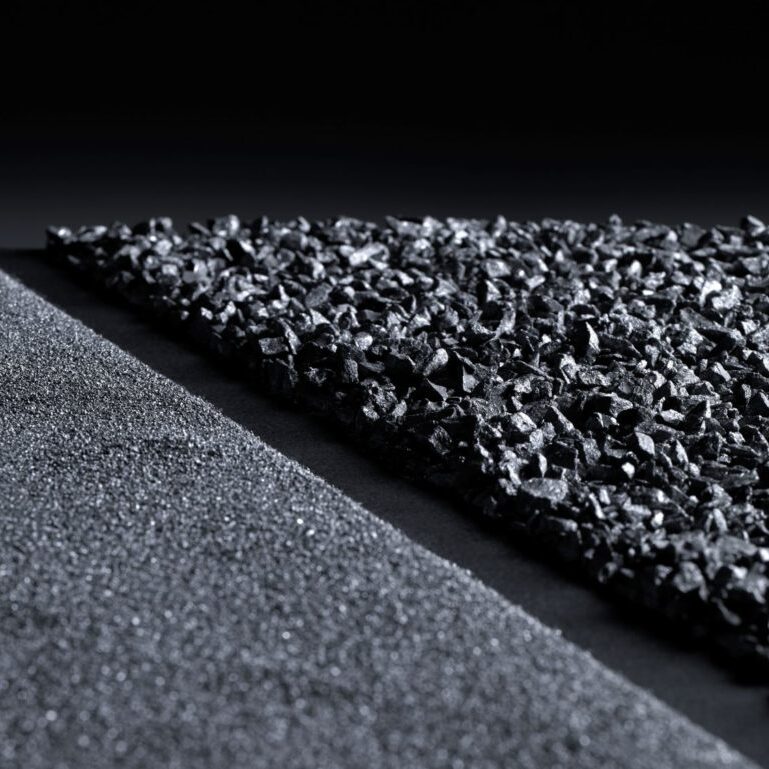

Carpenter Brothers, Inc. supplies an extensive range of inoculants to the metal casting industry. Inoculants are used for grey and ductile iron. A well-selected inoculant will help to eliminate the chill and bring the carbon out as graphite. If you do not get a good inoculation, you have a higher propensity for chill and to form carbides in the iron. This will give poor mechanical properties and be difficult to machine.

We warehouse the standard 75% Ferrosilicon Foundry grade inoculant used by many foundries. 75% & 50% FeSi regular is not an inoculant because it has too low a level of calcium and aluminum. For 75%, FeSi Foundry grade silicon is the inoculant carrier, and aluminum and calcium are the inoculants. As a standard rule, you will want a combined weight of aluminum and calcium of 2%. You can get away with lower levels, but you can end up with chill if you get too low. Also, if your sulfur content is too low in your iron, then the inoculant will not work.

We also provide a wide range of proprietary inoculants from Elkem. If you are getting carbides or chill in your iron, there is a good chance you need a more potent inoculant. The proprietary inoculants that we carry from Elkem can help you get good inoculation. The proprietary inoculants have various chemistries but can include strontium, zirconium, aluminum, barium, bismuth, or cerium. Carpenter Brothers can help you select the best inoculant for your application.

Inoculants Products

Carpenter Brothers, Inc. offers a complete line of foundry products to meet the requirements of the Metalcasting Industry.

Foundry Products

We supply the necessary foundry products you need to make a quality casting. Whether you need Metals & Alloys, Melting & Melt Quality, Molding & Core Making, Casting & Shakeout, Finishing & Surface Preparation, or Environmental Compliance products, we have what you need.

About Us

Carpenter Brothers, Inc. is the leading supplier of equipment, consumables, and technical expertise for the metal casting industry. Founded in 1917, by Everett and Milton Carpenter, the brothers were able to use their unique foundry experiences to solve the problem of the day: a reliable sand source. They got their foot in the door by selling natural bonded molding sand, which was mined by hand, loaded into horse-drawn carts, and then delivered to customers. Not only did they sell the sand, but their technical expertise was readily available for all customers, big or small, to help manufacture the best castings. After surviving The Great Depression, Carpenter Brothers, Inc. slowly increased the number of products it distributed and expanded its sales territory into what it is today.

Carpenter Brothers, Inc. has committed itself to its customer's success by providing exceptional service to go along with the superior products and equipment they supply. With multiple warehouses around the United States we can get you the products you need when you need them. Our logistics team can handle getting your order to you by truck, plane, or train. Our technical sales and engineering staff all have experience in the industry, so when you buy from Carpenter Brothers you gain access to all of our knowledge.