Riser Sleeves

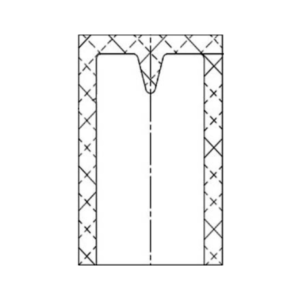

Riser sleeves are an essential part of any sand mold and help improve feeding efficiency. Riser sleeves are vacuum formed and inserted into the sand mold to allow a reserve of liquid metal to be readily accessible to feed the casting, preventing shrink and piping. In addition, the use of riser sleeves can help reduce heat loss allowing for a reduction in the size of the riser, helping increase yields and saving you money.

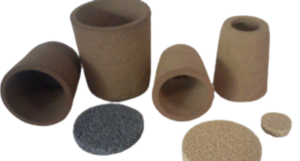

Our feeders and riser sleeves come in many different shapes and sizes. We offer the typical cylindrical riser sleeve, domes & spheres (with firecracker cores), blind risers, direct pours, neckdowns, and cone riser sleeves.

We offer insulating riser sleeves, exothermic, and high-performance riser sleeves. Insulating riser sleeves are designed to refract the heat from the liquid metal back into the casting, allowing the riser to keep a reservoir of molten metal readily available for feeding. Exothermic riser sleeves are designed for iron and steel castings. Exothermic riser sleeves rely on an exothermic reaction to increase the time that the metal is molten, increasing the casting feeding rate. We offer four types of exothermic riser sleeves, A mild exothermic material that does not ignite and is used when an insulating sleeve is not enough, a mild exothermic sleeve for when the metal needs to stay liquid longer, a high exothermic product that adds heat to the metal for better feeding efficiency, and an exothermic sleeve for manganese steel. Our high-performance riser sleeves are collapsable and cold box bonded, making them ideal for complex castings, including intricate designs and rapid molding processes. They achieve a higher casting yield than your typical insulating and exothermic riser sleeve.

Riser Sleeves Products

Carpenter Brothers, Inc. offers a complete line of foundry products to meet the requirements of the Metalcasting Industry.

Foundry Products

We supply the necessary foundry products you need to make a quality casting. Whether you need Metals & Alloys, Melting & Melt Quality, Molding & Core Making, Casting & Shakeout, Finishing & Surface Preparation, or Environmental Compliance products, we have what you need.

About Us

Carpenter Brothers, Inc. is the leading supplier of equipment, consumables, and technical expertise for the metal casting industry. Founded in 1917, by Everett and Milton Carpenter, the brothers were able to use their unique foundry experiences to solve the problem of the day: a reliable sand source. They got their foot in the door by selling natural bonded molding sand, which was mined by hand, loaded into horse-drawn carts, and then delivered to customers. Not only did they sell the sand, but their technical expertise was readily available for all customers, big or small, to help manufacture the best castings. After surviving The Great Depression, Carpenter Brothers, Inc. slowly increased the number of products it distributed and expanded its sales territory into what it is today.

Carpenter Brothers, Inc. has committed itself to its customer's success by providing exceptional service to go along with the superior products and equipment they supply. With multiple warehouses around the United States we can get you the products you need when you need them. Our logistics team can handle getting your order to you by truck, plane, or train. Our technical sales and engineering staff all have experience in the industry, so when you buy from Carpenter Brothers you gain access to all of our knowledge.