Sand

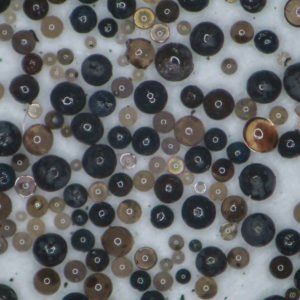

Carpenter Brothers, Inc. offers a full range of molding and core-making aggregates to meet all your foundry needs. The most abundant of our aggregate offerings is silica sand, the workhorse of the industry with a wide range of specialty blends to help with permeability (course) to surface finish (fine) and everything in between.

For high-temperature applications where penetration, burn-in, or dimensional stability are required, we offer various grades of zircon sand and ceramic sands, including mullites and bauxites.

Chromite sand, with its chilling effect and penetration resistance in steel and olivine sand for our non-ferrous customers looking for a non-wetting aggregate with excellent surface finish properties, is very popular and readily available.

Olivine Sand, although no longer mined domestically, it is still available from Norway. Most foundries utilize this sand as they did historically without issues. However, occasionally a foundry can produce pinholes, especially if what they are using is a straight, virgin facing sand. Therefore, it is best to meter it into the system sand after it has been premulled.

While most of the aggregates mentioned above can also be used successfully in many core-making processes, we also have a full line of core-specific sands in our offerings, including eco-friendly resin-coated sands with improved flowability and excellent knockout characteristics, including fused silica.

We offer zircon flour and ceramic flours for your slurries to produce refractory shells for our investment casting foundries. We also supply low-density (LD), and intermediate-density (ID) aggregates as backing material during pour-off.

Sand Products

Carpenter Brothers, Inc. offers a complete line of foundry products to meet the requirements of the Metalcasting Industry.

Foundry Products

We supply the necessary foundry products you need to make a quality casting. Whether you need Metals & Alloys, Melting & Melt Quality, Molding & Core Making, Casting & Shakeout, Finishing & Surface Preparation, or Environmental Compliance products, we have what you need.

About Us

Carpenter Brothers, Inc. is the leading supplier of equipment, consumables, and technical expertise for the metal casting industry. Founded in 1917, by Everett and Milton Carpenter, the brothers were able to use their unique foundry experiences to solve the problem of the day: a reliable sand source. They got their foot in the door by selling natural bonded molding sand, which was mined by hand, loaded into horse-drawn carts, and then delivered to customers. Not only did they sell the sand, but their technical expertise was readily available for all customers, big or small, to help manufacture the best castings. After surviving The Great Depression, Carpenter Brothers, Inc. slowly increased the number of products it distributed and expanded its sales territory into what it is today.

Carpenter Brothers, Inc. has committed itself to its customer's success by providing exceptional service to go along with the superior products and equipment they supply. With multiple warehouses around the United States we can get you the products you need when you need them. Our logistics team can handle getting your order to you by truck, plane, or train. Our technical sales and engineering staff all have experience in the industry, so when you buy from Carpenter Brothers you gain access to all of our knowledge.