Silica Sand

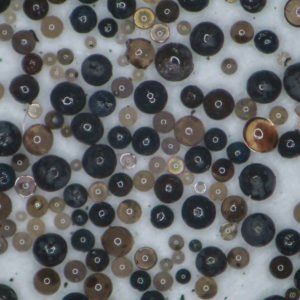

Our Core and Mold Foundry Sands are produced from high purity, monocrystalline industrial quartz. Chemically inert and free of clays or other organic materials, the round and sub round grains of our silica sands will significantly improve a foundry’s dimensional accuracy, mold and core making efficiency, and production costs. The lower total surface area and point-to-point contact of round and sub-round silica sands require fewer resins, catalysts, and additives to maximize binder performance and tensile strengths. Round grain geometry improves the core-making process with more efficient placement, better void spacing for optimal curing, and consolidation for excellent resistance to metal penetration while effectively transferring and dissipating pouring temperatures. Following the pour, round grain silica sand can improve shakeout efficiency and yield better-suited sand for reclamation and reuse.

We offer our silica sand in 50 lb bags, super sacks, and truckloads. The grain finenesses we supply range from 30 through 120 so that you can meet the exact composition and quantity your foundry needs.