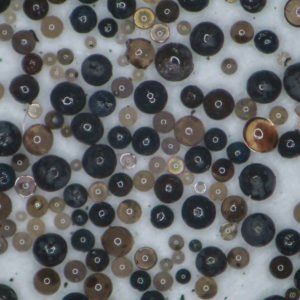

Coated (Shell) Sand

Shell sand is coated under heat with a flake thermosetting phenolic resin and catalyst. Shell sand is manufactured and shipped in various packaging options to foundries. The cold, flowable sand is blown into the mold or core pattern cavities preheated to 230-350 degrees F. The core box is held with sand for the required amount of time to allow the shell sand to set, then rotated to drain the interior unset sand. Thus, creating a shell core or mold.

Carpenter Brothers, Inc. supplies numerous resin-coated sand blends. We sell silica, olivine, zircon, and zircore resin-coated sands in various AFS grain finenesses. The resin percentage can range from 0.8% to 5%. In addition, there are multiple additives and release agents that we can add to the resin-coated sand. Contact us to recommend a solution for your project.