Specialty Sands

The use of silica sand as a molding and/or core aggregate is very economical. However, there are occasions where the use of silica sand with conventional binders and additives does not give satisfactory casting results. When expansion defect problems such as veining occur, or if you are experiencing burn-on, metal penetration, or poor casting surface finish, the use of a specialty sand may be the answer.

Below are the specialty sands available from Carpenter Brothers:

Zircon Sand

Zircon sand is composed of the mineral zirconium silicate (ZrSiO4). The best commercial deposit of zircon sand in the U.S.A. is in Florida. Zircon sand has a bulk density of approximately 170 lbs. per cubic foot. When all impurities are removed through a calcining process, it has a melting point of over 4000° Fahrenheit. The AFS grain fineness number of the Florida calcined zircon sand is approximately 110, with a three (3) screen distribution sand. Zircon sand is also available from Australia with an AFS grain fineness range of 65-72.

The outstanding property of zircon sand, similar to chromite sand, is that it is not easily “wetted” by molten metal. There is little friction when metal flows across a zircon mold or core surface, thus improving casting surface finish.

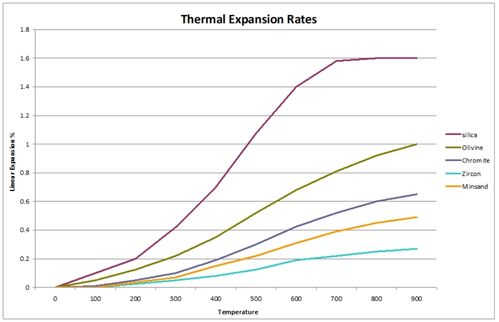

Zircon sand has the least amount of thermal expansion of the specialty sands and therefore is an excellent sand to use when trying to eliminate veining and other expansion defects. Mixtures of silica sand and zircon sand are common throughout the metalcasting industry.

Chromite

Chromite sand has a bulk density of approximately 160 lbs. per cubic foot.For comparison, silica sand has a bulk density of approximately 100 lbs. per cubic foot. The mineral composition of chromite sand is a spinel phase group of Cr2O3·Al2O3·MgO·FeO with a chemical composition of 45-50% chromic oxide. Chromite sand has an AFS grain fineness number of 50/60, and has a (4) screen distribution.

Chromite sand is not easily “wetted” by molten metals. It is particularly resistant to metallic slag attack, and is a superior molding medium in the casting of high manganese steels, and other reactive alloys.It also has a high heat transfer and absorption rate, and can be used where chilling or controlled directional solidification of the metal is desirable.

Chromite is ideally suited for cores which are susceptible to burn-on, metal penetration, or veining. Very low binder requirements are used for bonding chromite sand mixtures.

Olivine

Olivine is a natural mineral consisting of a solid solution rich in magnesium ortho-silicate (forsterite), and iron ortho-silicate (fayalite) as a minor component.There are several grades of olivine available between 45 and 120 AFS Grain Fineness Numbers.

As a foundry sand, olivine is noted for its high fusion point and low uniform thermal expansion. Like the other specialty sands, olivine is very resistant to metal penetration and expansion defects. Since olivine sand is basic (higher pH than silica), it is ideally suited for the casting of manganese steel. The basicity of olivine, however, limits its use in acid catalyzed resin systems.

Olivine is an excellent green sand molding aggregate in non-ferrous foundries. Many aluminum and copper base alloy foundries are using olivine with great success. The elimination of scabbing and other expansion type defects, along with excellent surface finish, are olivine’s big advantages.

Zircore

Zircore is a mineral which occurs in the zircon deposit in Florida. In addition to the mineral zircon, Zircore has approximately 3% to 7% staurolite present. It has an AFS grain fineness number of 90-105.

Zircore is primarily used in gray ductile iron foundries for reducing veining. It can be used in combination with silica and/or chromite sand.

Mineral Sands

Mineral Sand is high Alumina calcined bauxite. It is a spherical grain that has a very smooth surface that is easily coated. Castings can be produced in non-ferrous, ductile, gray iron and steel. It has a pH of 7.5 and can be used on almost all types of resin systems. As seen in the graph below, it has a very favorable expansion rate when compared to Zircon. The grain fineness available is 50 AFS, 65 AFS and 90 AFS.

If you have a particular casting application that could benefit from the use of a specialty sand, please call us. We at Carpenter Brothers, Inc. have had a lot of experience with these sands in many areas, therefore we are happy to recommend molding and/or core sand mixtures using these sands.