When Dust Collection Becomes a Strategic Advantage in Foundry Sand Systems

By Jay M. Morrison – Carpenter Brothers, Inc.

Walk into any foundry and you’ll see dust everywhere—around shakeout decks, along sand conveyors, in the sand tower, and hanging in the air above a busy muller floor. Foundries move, reclaim, and cool tens of thousands of pounds of sand every hour, and every transfer point, screen, or elevator is an opportunity for airborne dust to escape.

While it’s easy to think of dust control as just a compliance issue, it’s much more. Effective dust collection is a fundamental metric for foundry process control impacting health, quality, efficiency, equipment life, and sustainability.

More Than Clean Air — Controlling the Process

Dust collection starts with protecting people, but the benefits extend deep into the sand system. Respirable crystalline silica exposure remains one of the most closely regulated hazards in metalcasting, and a well-designed collection system helps meet OSHA, EPA, and NFPA requirements.

At the same time, dust capture directly influences sand consistency and casting quality. When fine particles escape the loop, they change the grain fineness number (GFN), surface area, and distribution of the molding aggregate. Over time, that variability can affect key properties such as mold strength, gas evolution, and surface finish.

Maintaining the right balance of fines keeps the sand system predictable and repeatable—exactly what foundries need to hit dimensional and mechanical targets.

Engineering the Right System

No two foundries are the same, which means there’s no “one-size-fits-all” dust collector. The right solution depends on the process layout, material movement, and air balance across the building.

Design matters! A dust collection system must move the correct volume of air from each source without upsetting the overall building balance. If air in doesn’t equal air out, the result can be lost capture velocity, poor hood performance, or unwanted drafts through doors and openings. Modern design tools such as Computational Fluid Dynamics (CFD) help visualize these flows before fabrication. CFD modeling allows engineers to optimize duct size, pressure drop, and capture velocity for efficiency and energy savings.

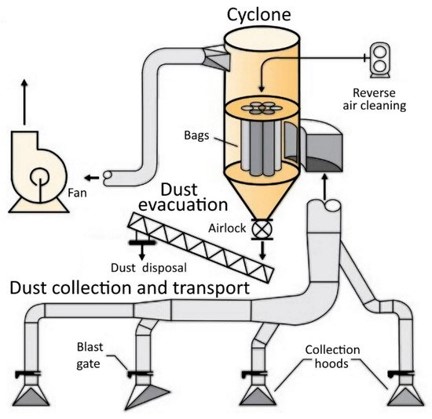

Typical foundry systems may use pulse-jet or reverse-air baghouses, flat or pleated filters, and pre-separators or cyclones. The key is to design for proper cleaning energy and an appropriate air-to-cloth ratio. Undersized systems tend to clog quickly while oversized systems waste power and money.

Integration Throughout the Sand System

Dust collection shouldn’t operate in isolation. The best systems are fully integrated into the sand handling and reclamation loop, capturing dust where it’s created:

- Sand transport: Conveyors, bucket elevators, and pneumatic lines.

- Mulling and mixing stations: Preventing contamination and loss of working foundry sand grain bonding consumables, such as bentonite clay.

- Shakeout operations: Reducing silica release during cooling and screening.

- Sand reclamation: Controlling binding fines, VOCs & HAP’s, and combustion residue.

Each of these stages contributes to the overall cleanliness and performance of the sand system. When designed correctly, the foundry gains not only better air quality but also more consistent sand characteristics.

Reclamation and Sustainability

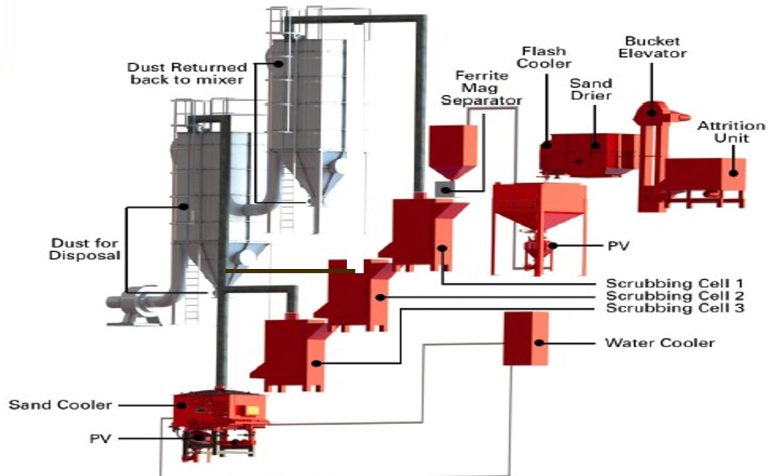

One of the biggest wins from effective dust control is sand reuse. High-efficiency systems allow foundries to become their own supplier—reclaiming clean, low-LOI sand that can be reintroduced into production.

Whether through mechanical attrition or thermal reclamation, dust collection plays a critical role in:

- Removing fine sand and binder particles, including dead clays

- Controlling carry-over dust during cooling and fluidization.

- Reducing new sand additions and landfill waste.

Every ton of reclaimed sand represents direct cost savings, reduced environmental footprint, and improved consistency in the molding process.

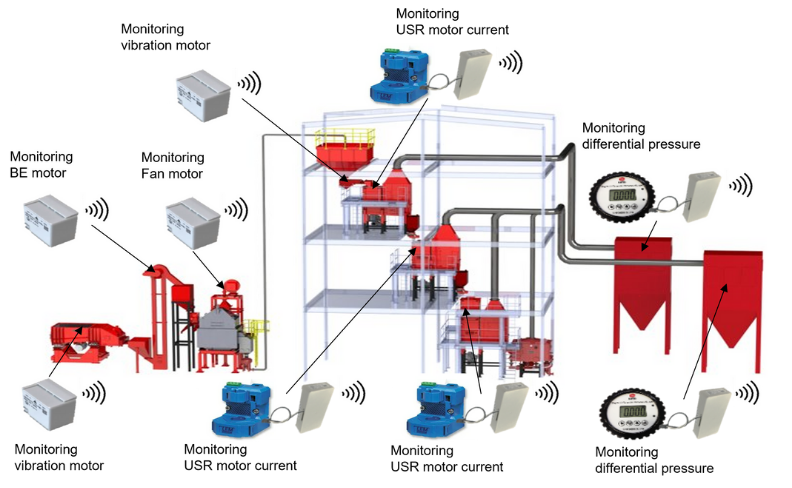

Maintenance and the Foundry 4.0 Connection

A dust collector’s performance depends on maintenance discipline. Periodic measurement of airflow and capture velocity at key points allows early detection of system imbalance. Collectors should be mapped, tested, and the dust itself analyzed, including regularly checking GFN, distribution, surface area, LOI, moisture, and surface area to understand what’s really being removed from the process regardless of the binder system. In addition, specifically to green sand systems, it is important to trend clay content, often by Methylene Blue test. For chemically bonded systems, additional testing for nitrogen, sulfur, and phenol/free formaldehyde is recommended.

In modern systems, sensors provide automatic monitoring. Foundry 4.0 technologies can track and evaluate differential pressure, velocity probes, temperature and particulate sensors can provide continuous feedback on collector performance. The data enables predictive maintenance, energy optimization, and performance analytics across the entire sand system.

The Bottom Line

Dust collection is not a bolt-on accessory or a compliance afterthought—it’s a crucial component of foundry performance. When engineered into the sand system, a well-balanced collection network:

- Protects workers and ensures regulatory compliance.

- Improves casting quality through stable sand characteristics.

- Extends the life of mixers, mullers, screens, and conveyors.

- Reduces operating costs through energy efficiency and sand reuse.

In short, good dust collection doesn’t just suck—it delivers.

For more information on optimizing your foundry’s sand and dust collection systems, contact the experts at Carpenter Brothers, Inc. We work closely with foundries and equipment suppliers worldwide to design integrated systems that balance safety, quality, and performance.