Sand Reclamation

Problem: Increasing Sand, Freight, and Landfill Costs

Between the rising price of new high-purity silica sand, the cost to move it to your foundry, and landfill tipping fees, “white gold,” the term used for years by the oil fracking industry to describe silica sand, now applies to the foundry industry as well.

Solution: Sand Reclamation

All foundries should have a good understanding of what their sand costs are, particularly those running expensive ceramic sands which are gaining in popularity due to increasingly tightening environmental regulations.

The systems available to the foundry industry have been refined and further developed to reduce waste sand and new sand purchases. Many foundries have already made the move to sand reclamation but may be looking at additional means to reduce waste sands. It would be nice if one prescription could be written to cure all the waste sand problems, but not all foundries have been created equal. Each foundry must take a close look at their sand usage and do a material balance to determine what is best for them.

Sand Reclamation Options

Attrition Mills

- Provide a means to reduce lumps, primarily chemically bonded sands, to a screen distribution that can be reused in the sand system in a limited quantity.

- Lower sand-to-metal ratios provide greater thermal decomposition during the casting process and increase the amount of sand for reuse through the attrition mills. Some foundries can use as much as 75% reclaim and 25% new sand depending on the application.

- Provide a method to recycle scrap cores back into the core room, because the scrubbing action is minimal. It is recommended that small quantities (5-10%) be added back to the core sand mix.

- Used in the first step to reduce the sand to a usable size to feed a secondary unit, such as a scrubber or thermal sand reclamation. It is also used in the first stage of green sand to core room reclamation.

Scrubbers

- Provide a secondary stage to remove additional residuals after the sand has passed through an attrition mill. This process is primarily an impingement process using sand-on-sand contact for a controlled period, and then a method of removing fines that contain most of the waste binders.

- Provide reclaimed sand that can be used in greater quantities within the system. Foundries have reported ratios of 90% reclaim to 10% new sand. More typical would be 75% reclaim to 25% new, depending on sand-to-metal ratios and binder system. This process has been used effectively to scrub green sand of dead clays and residual binders for reuse in a green sand system.

- Used in combination with thermal sand reclamation systems, where most of the waste sand is processed through the scrubber, and approximately 15% is processed through a thermal unit and is added back as new sand. This creates a nearly closed-loop system where only small amounts of sand must be replaced due to losses in the process.

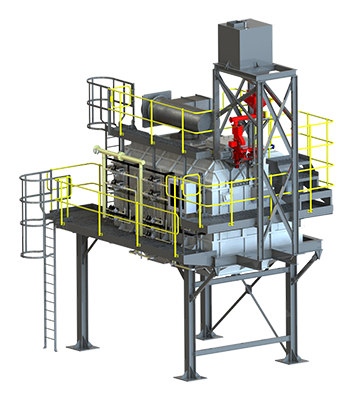

Thermal Reclamation

- Provides an efficient method for the removal of residual binders and provides sand close to the new sand quality. Lumps must be reduced in size in an attrition mill to be processed in the fluid bed thermal reclaimer. Once the sand leaves the thermal reclaimer, it enters a fluid bed cooler to cool to a desired operating temperature. Thermal reclaimers operate at a temperature of around 1500F and the retention time in the unit can be increased or decreased, depending on the final loss on ignition desired.

- Used for chemically-bonded sands and as part of the process when reclaiming green sand for the core room.