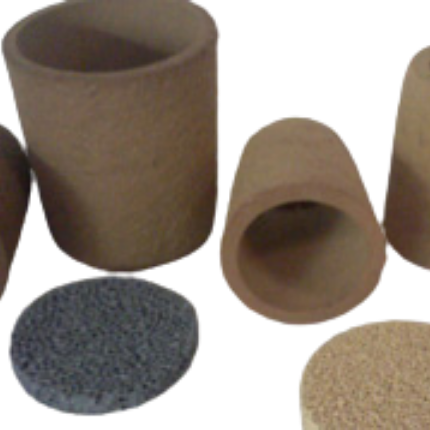

Direct Pours

Direct pours are used as a pouring cup, placed right above the down sprue. They are designed wider at the top, tapering down to allow space for a filter. This allows the operator to pour the casting easier. In addition, the direct pours provide a larger cup to pour metal into. A filter provides a less turbulent metal stream to the mold cavity while trapping oxides, slag, dross & other non-metallic material. Direct pours can be manufactured with an oil sand breaker core to reduce the contact area. We offer silicon carbide filters for grey and ductile iron castings and zirconia filters for steel castings. Direct pour sleeves are designed by the filter size ranging from 2” to 8” in diameter.

Foundry Products

We supply the necessary foundry products you need to make a quality casting. Whether you need Metals & Alloys, Melting & Melt Quality, Molding & Core Making, Casting & Shakeout, Finishing & Surface Preparation, or Environmental Compliance products, we have what you need.

About Us

Carpenter Brothers, Inc. is the leading supplier of equipment, consumables, and technical expertise for the metal casting industry. Founded in 1917, by Everett and Milton Carpenter, the brothers were able to use their unique foundry experiences to solve the problem of the day: a reliable sand source. They got their foot in the door by selling natural bonded molding sand, which was mined by hand, loaded into horse-drawn carts, and then delivered to customers. Not only did they sell the sand, but their technical expertise was readily available for all customers, big or small, to help manufacture the best castings. After surviving The Great Depression, Carpenter Brothers, Inc. slowly increased the number of products it distributed and expanded its sales territory into what it is today.

Carpenter Brothers, Inc. has committed itself to its customer's success by providing exceptional service to go along with the superior products and equipment they supply. With multiple warehouses around the United States we can get you the products you need when you need them. Our logistics team can handle getting your order to you by truck, plane, or train. Our technical sales and engineering staff all have experience in the industry, so when you buy from Carpenter Brothers you gain access to all of our knowledge.