Managing Your Plant’s Combustible Dust

Combustible dusts are fine particles that present an explosion hazard when suspended in air under certain conditions. Dust explosions can cause destruction of property, injuries, and loss of life. The Federal Government has updated the National Fire Protection Association (NFPA-68) regulation from a guideline to a standard in 2008. The revised NFPA 68 affects how you handle your plant’s combustible dust in five ways:*

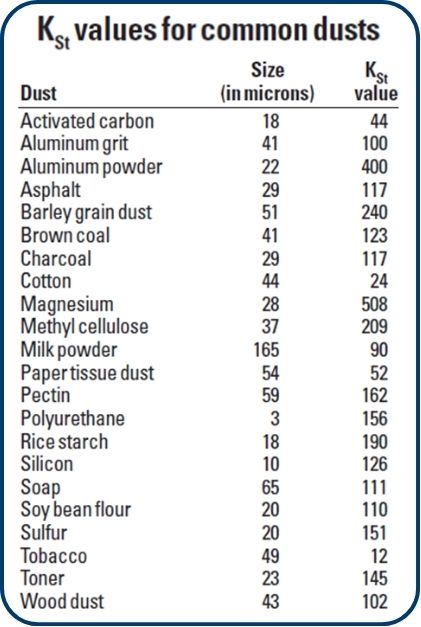

In the closed area of a dust collector, an explosion can occur when a large concentration of dust is put in contact with a spark that is sucked into the chamber. NFPA classifies dust according to its explosibility (dust deflagration index, K ). K measures the relative explosion severity compared to other dusts. It is defined as the normalized rate of rise of explosion pressure. There are only a few inert dusts that resist explosions. Aluminum dust is particularly high on the list. The following table taken from Powder Bulk & Engineering, July 2008 lists the K values for many common dusts.

The NFPA-68 standard covers explosion protection by deflagration venting. The NFPA-69 standard describes the methods used to prevent and mitigate combustible dust hazards such as inerting systems and oxygen concentration reduction. Since NFPA-68 and NFPA-69 have been changed from guidelines to standards, anyone installing a new dust collector or moving an existing system, and those manufacturers collecting dust should acquire a copy of these standards to ensure that they comply.