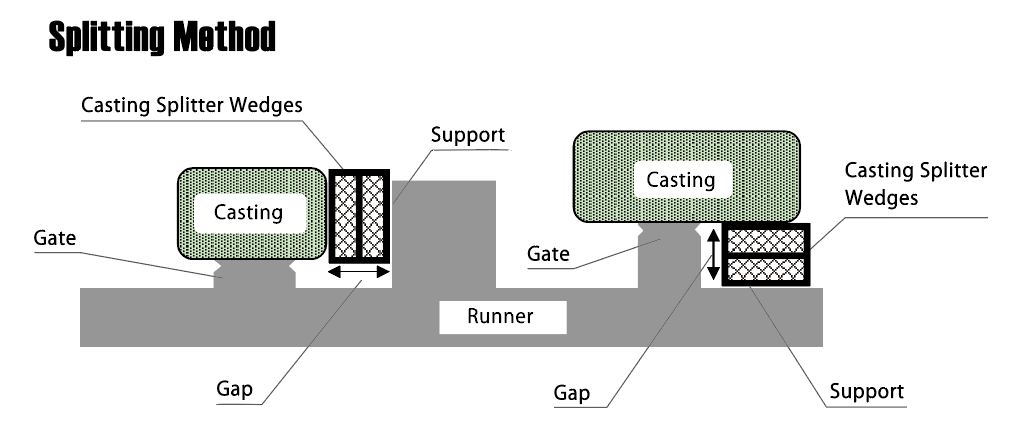

The EP-Series Casting Splitter is a cutting-edge solution engineered for the rapid and secure separation of gates from iron castings. Unlike traditional methods such as hammering, plasma cutting, and grinding, the EP-Series provides a highly efficient, safe, and precise alternative for this critical task. By streamlining the gate removal process, it significantly improves operational efficiency. It also reduces the risk of damage to the castings, ensuring their integrity is maintained throughout the process.

At the heart of the EP-Series is Hirado’s proprietary pump, which allows for fast, controlled, and accurate gate removal. The pump system is designed to operate with high precision. This ensures that gates are removed without compromising the surrounding material or the overall casting structure. This precision is essential in industries where even the slightest imperfection can lead to costly defects or rework.

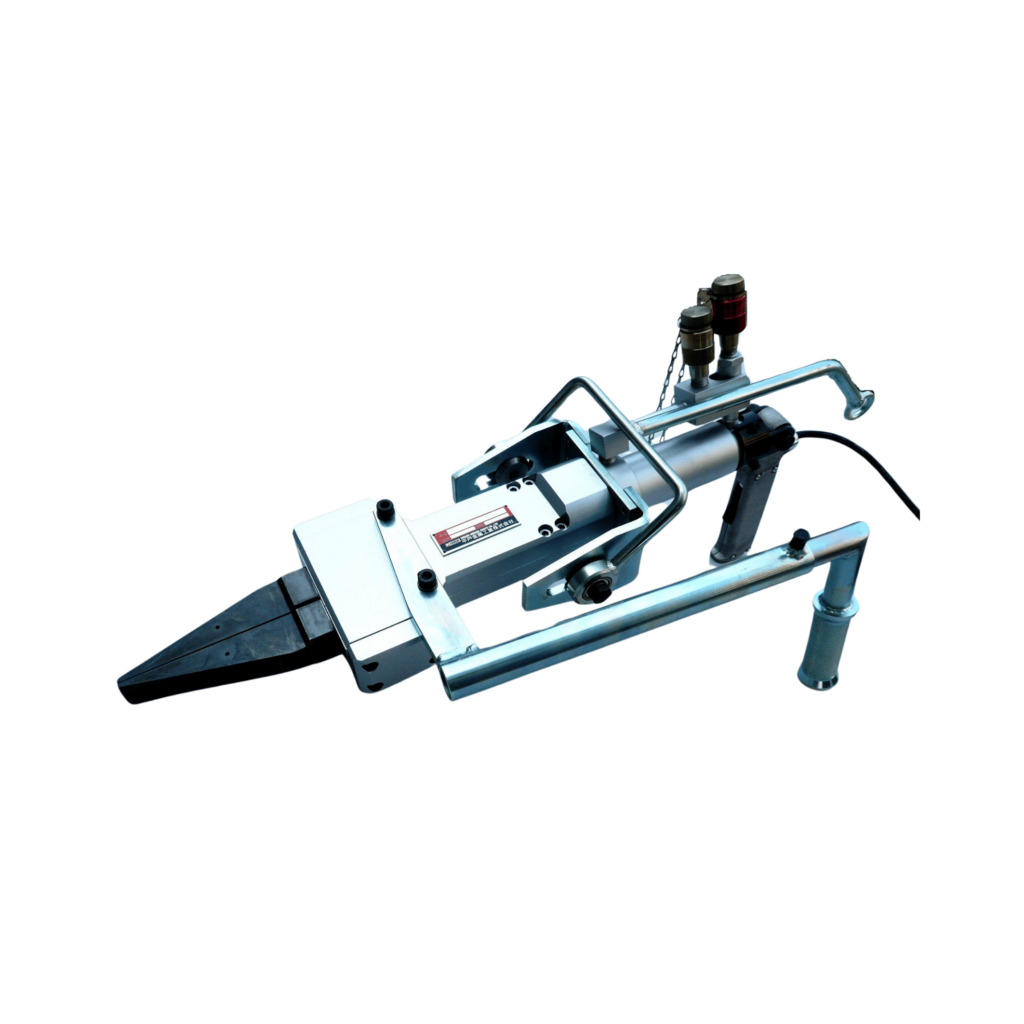

One of the key features of the EP-Series is its lightweight and compact design, which makes it easy to handle and operate in tight spaces. The unit is also fully rotatable, offering unparalleled flexibility and the ability to achieve accurate splitting from a variety of angles. This adaptability makes the EP-Series suitable for a wide range of industrial environments, from small workshops to large-scale foundries.

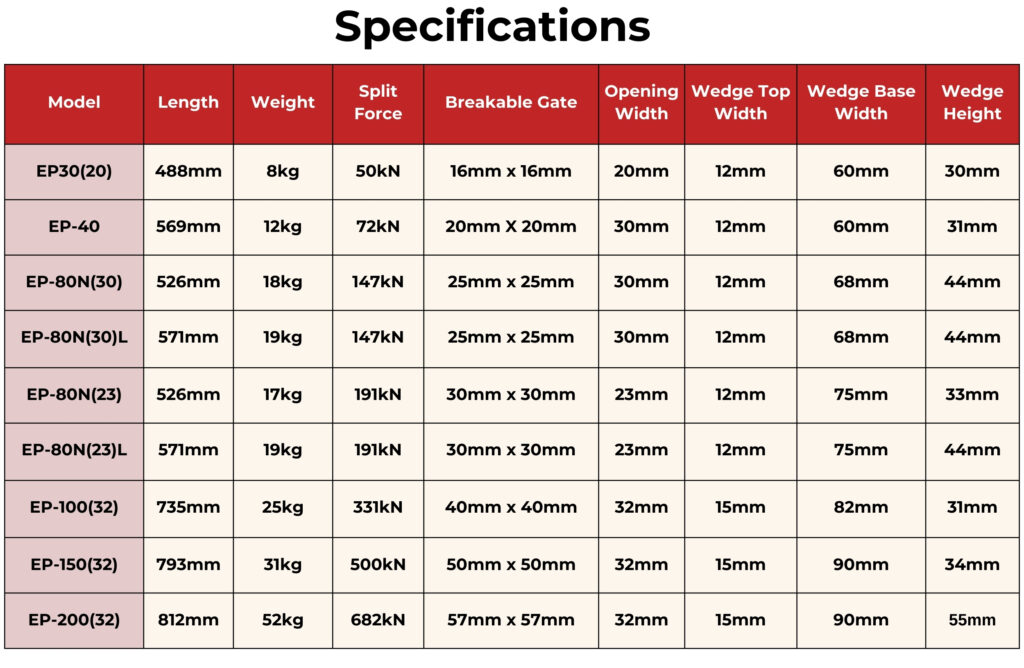

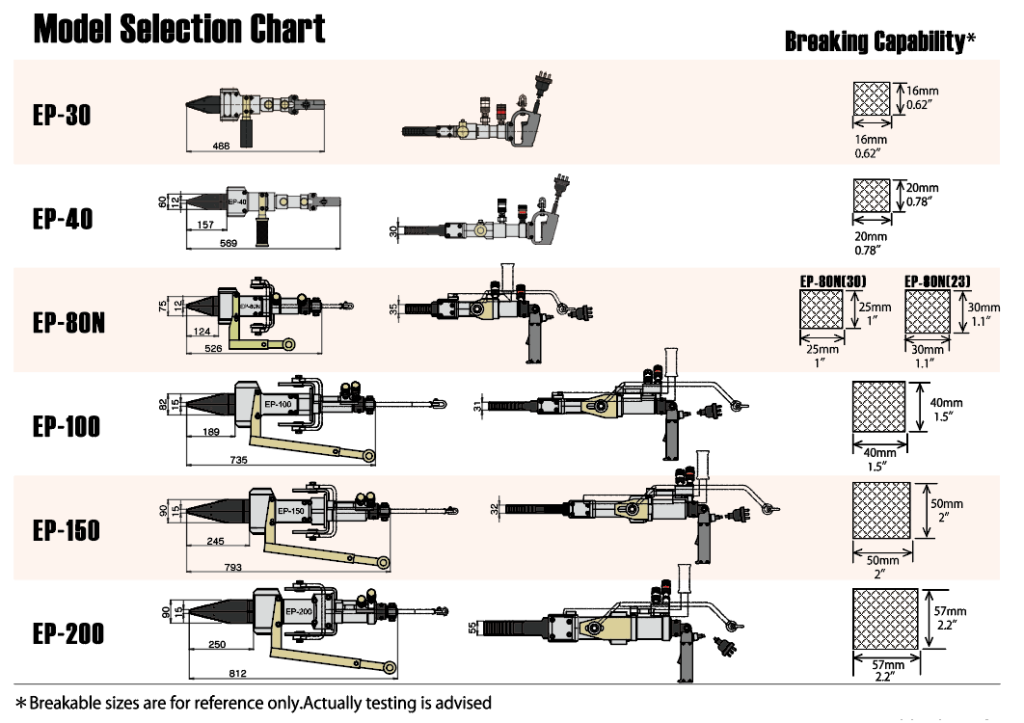

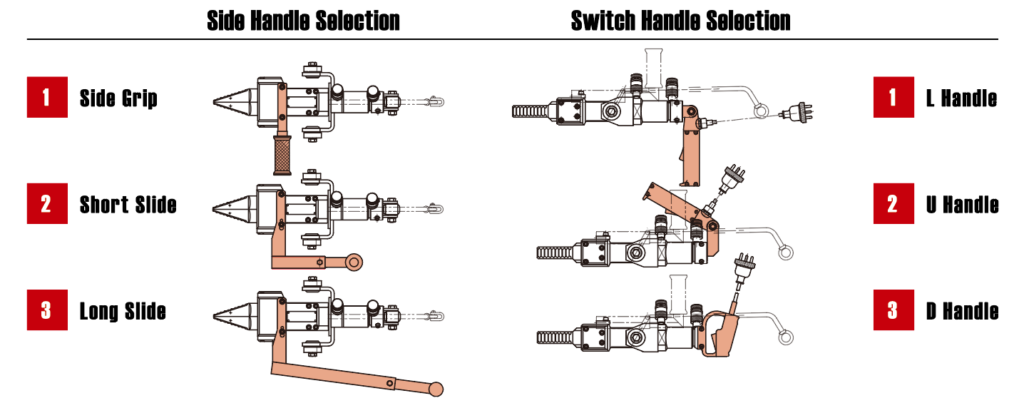

Additionally, the EP-Series Casting Splitter is available in a range of models. Each is tailored to suit different gate sizes and power specifications. These models can be fully customized with a variety of handle options. This allows users to adjust the splitter to their specific conveyor belt configurations and workspace conditions. With its versatile design and robust performance, the EP-Series is an ideal choice for those seeking an advanced, reliable solution for gate separation in iron casting operations.