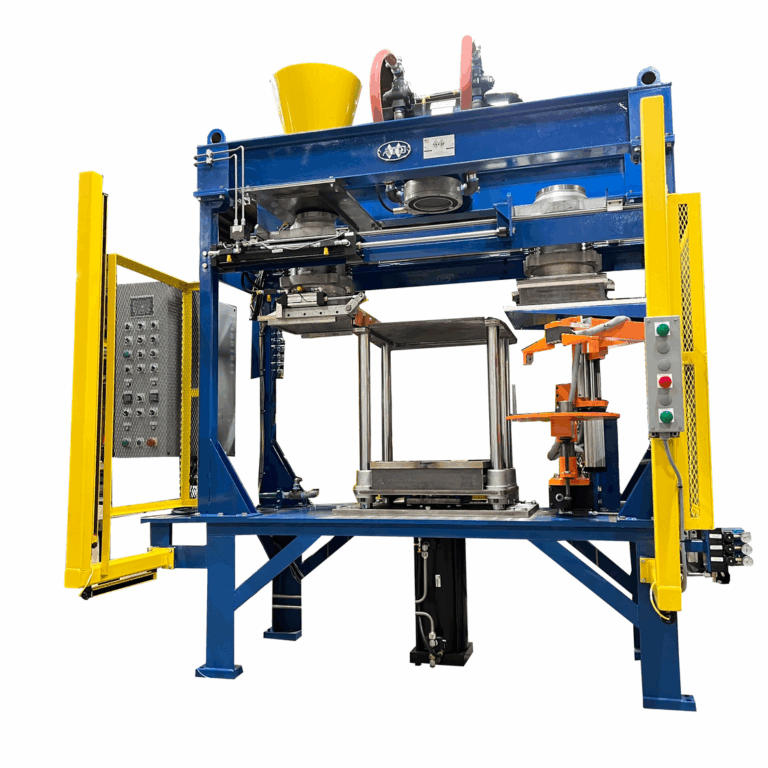

Hot Box Core Machines

The most complete range of hot box core machines and auxiliary equipment. The proportional gas control system allows savings on gas and utility cost while maintaining precise core box temperature control during the operation. Available for a wide range of production needs and conditions. The systems can be installed in high production – automotive applications.

Efficient Hot Box Core Machines for High-Volume Foundries

ATD designs and manufactures one of the industry’s most complete lines of hot box core machines. These machines are purpose-built for demanding, high-output casting environments. As an authorized distributor, Carpenter Brothers provides foundries with the technical expertise to help select the right configuration for your process.

Whether your facility produces complex cores for automotive casting or handles high-throughput jobs across multiple shifts, ATD systems are engineered to deliver efficiency, repeatability, and control.

Energy Efficiency Meets Process Precision

A key feature of ATD’s hot box core machines is their proportional gas control system. This technology allows for tight control of core box temperatures during the curing process — helping ensure dimensional accuracy and consistent core quality — while also providing energy efficiency through optimized gas usage. This results in measurable utility savings over time, especially in high-production environments.

Key Features of ATD Hot Box Core Systems

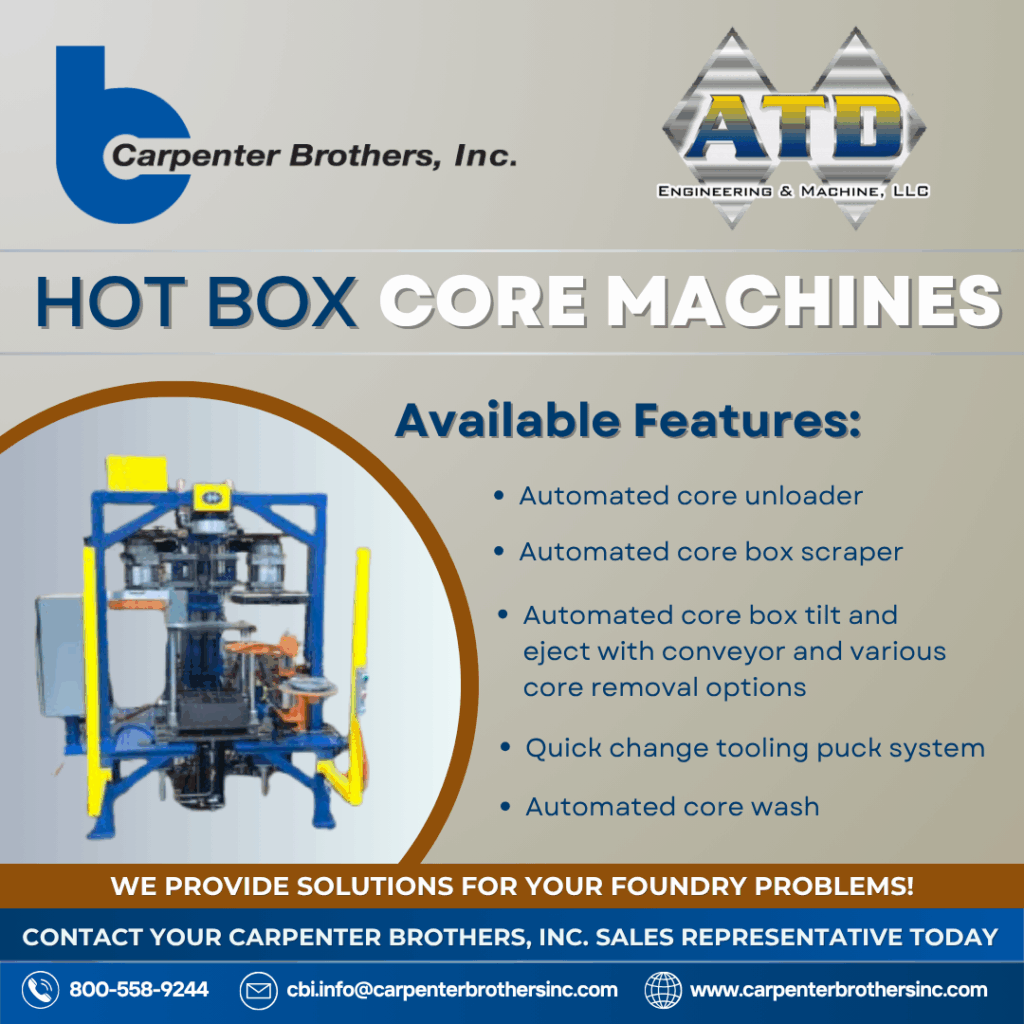

ATD equipment can be tailored to fit your production needs, offering a wide range of automation and operator-assist features:

-

Automated Core Unloader

Reduces manual handling and improves core transfer speed post-ejection. -

Automated Core Box Scraper

Helps keep invest areas clean between cycles, reducing buildup and defects. -

Core Box Tilt & Eject with Conveyor Options

Especially useful for vertical core boxes, with various configurations for safe, efficient core removal. -

Quick-Change Tooling Puck System

Speeds up changeovers and allows for greater flexibility in multi-part production. -

Automated Core Wash Systems

Provides in-line coating capabilities, helping streamline core finishing and reduce handling.

All machines are built with heavy-duty construction and user-friendly maintenance access, making them suitable for continuous operation in automotive and industrial foundries.

Scalable Solutions for High-Production Core Making

ATD’s hot box systems are widely installed in high-volume automotive foundries, as well as in industrial settings with specialized coremaking requirements. The equipment is compatible with a variety of tooling layouts and casting processes, and it can be integrated into automated lines or stand-alone work cells depending on your facility’s production model.

Whether you are manufacturing engine components, suspension elements, or housing castings, ATD hot box systems are engineered to perform reliably across thousands of cycles.

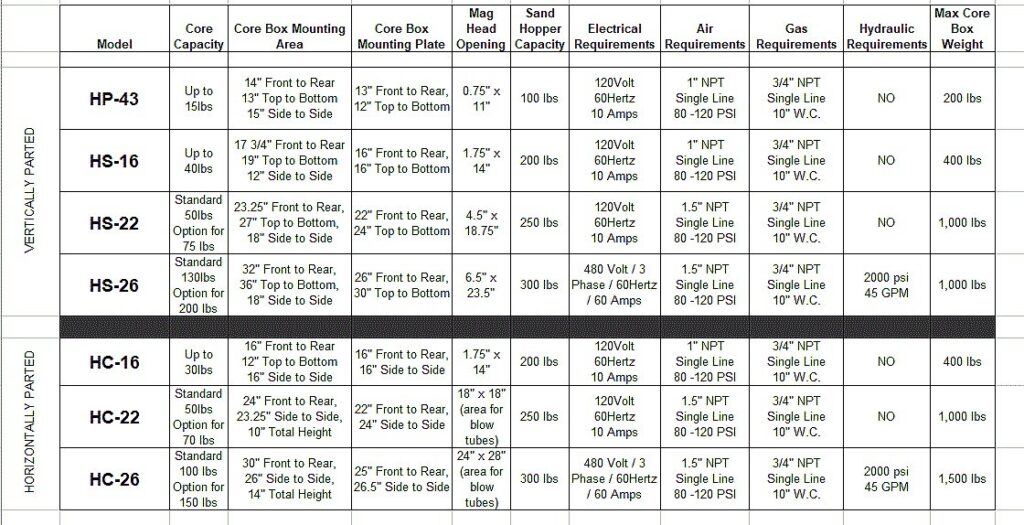

Core Capacity per Model:

- HP-43 | Up to 15lbs

- HS-16 | Up to 40lbs

- HS-22 | Standard 50lbs/Option for 75lbs

- HS-26 | Standard 130lbs/Option for 200lbs

- HC-16 | Up to 30lbs

- HC-22 | Standard 50lbs/Option for 70lbs

- HC-26 | Standard 100lbs/Option for 150lbs

Max Core Box Weight per Model:

- HP-43 | 200lbs

- HS-16 | 400lbs

- HS-22 | 1,000lbs

- HS-26 | 1,000lbs

- HC-16 | 400lbs

- HC-22 | 1,000lbs

- HC-26 | 1,500lbs

Supporting Your Operation with Proven Equipment

As a distributor of ATD equipment, Carpenter Brothers provides:

-

Consultation on selecting the right machine size and configuration

-

System integration guidance and layout planning

-

Access to factory support and technical documentation

-

Recommendations for auxiliary equipment based on your casting process

We work closely with both your engineering and production teams to ensure the equipment delivered matches your foundry’s throughput, material, and quality requirements.

Supporting Your Casting Operation

At Carpenter Brothers, our role is to provide practical guidance and connect metal casters with the right equipment for their production goals. If you’re exploring options for upgrading your casting systems or need support selecting the right configuration, we’re here to help.

Whether you’re evaluating automation needs, planning a facility upgrade, or simply gathering information, we’re available to answer questions and share technical resources.

Learn More or Start a Conversation

If you’d like to learn more about ATD’s hot box core machines or discuss potential applications in your operation, feel free to reach out.