FerroNiobium (FeNb)

FerroNiobium (FeNb), also known as columbium, is widely used as a grain refiner in steels to enhance strength and durability. In foundry applications, it is essential for high-temperature stainless steel grades, particularly in turbo components. FeNb is also increasingly used in gray cast iron to produce longer-lasting brake discs and drums, offering improved wear resistance and performance. An effective solution for alloying with niobium, FeNb helps foundries achieve superior casting quality and durability.

Niobium, also known as columbium, is a valuable alloying element used to enhance the performance of cast irons and steels in foundry operations. In most applications, it is introduced as Fe Niobium (FerroNiobium), a cost-effective and efficient master alloy.

Alloying with niobium improves mechanical properties by refining grain structure, increasing strength, and enhancing resistance to heat, wear, and corrosion. These improvements make it ideal for high-performance castings such as automotive components, turbine parts, tool steels, and wear-resistant iron grades.

By forming stable carbides and strengthening the microstructure, niobium reduces defects, improves casting quality, and enhances overall durability. Its use also supports better weldability and high-temperature stability.

For foundries seeking improved casting performance and longevity, alloying with niobium or FerroNiobium provides an effective solution.

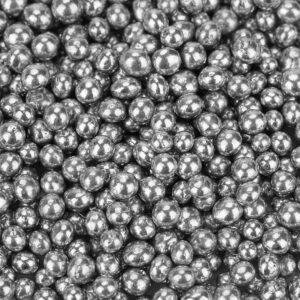

Sizing

Lump – 5 – 50mm

Fines – < 5mm

Briquettes – 25mm x 45mm x 60mm

Packaging

550 lb. drums

2204 lb. super sacks