Bismuth (Bi)

Bismuth is used in foundries to improve machinability, reduce shrinkage, and serve as a non-toxic alternative to lead in both ferrous and non-ferrous castings, enhancing casting quality and safety.

Iron Applications – Incorporated in select inoculant formulations at concentrations of 0.5–1.0%, Bismuth helps reduce chill depth and enhances graphite nucleation, leading to improved casting structure and consistency.

Non-Ferrous Applications – Used to improve machinability and reduce brittleness in copper-based alloys, Bismuth also serves as an effective, non-toxic alternative to lead in various alloy systems.

Bismuth (Bi) – High-Purity Metal for Iron & Non-Ferrous Foundry Applications

Bismuth (Bi) is a non-toxic, heavy metal known for its unique properties, making it a valuable alloying and metallurgical additive in foundry operations. Ideal for use in both iron and non-ferrous foundry applications, offering reliable performance in a wide range of casting environments.

In iron foundries, Bismuth is commonly used as an inoculant or alloying element in compacted graphite and gray iron. It enhances machinability and promotes uniform graphite formation, improving casting consistency and surface quality. Bi can also replace lead in certain formulations, providing a safer alternative that complies with increasingly strict environmental and health regulations.

In non-ferrous foundries, Bismuth is widely used in low-melting alloys, brass and bronze systems, and fusible alloys for safety devices and precision casting. Its expansion upon solidification makes it useful in applications requiring tight dimensional control. Additionally, Bi contributes to improved castability and reduced porosity in various alloy systems.

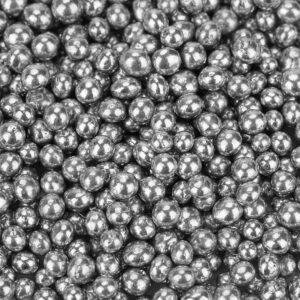

Carpenter Brothers offers Bismuth (Bi) in multiple sizes and packaging, including Bismuth Shot 0.125”. Contact us for availability.